Since our establishment in 2005, Shenzhen Ritian Technology Co.,

Ltd have been manufacturing protection film solutions for

industries across the board. Specializing in a vast array of

surface protection film for a multitude of purposes, we have been

providing cost-effective, reliable products for decades.

Created in our 108,000ft manufacturing facility in Shenzhen, China,

our protection films are applicable to a wealth of uses – including

construction, automotive , Aluminium Profiles, Pre Painted Metals,

Plastic Sheets, Domestic Appliances and Electronic devices –

there’s something suited to every industry.

With 100% of our product selection produced in-house, you can rest

assured that your purchase will be of a high quality, meticulously

manufactured by a company with an extensive history of experience

to draw from.

Since establishment, we have decided to be focus on the surface

protection films industry, and we have endeavored to keep up with

the changes and demands in the industry.

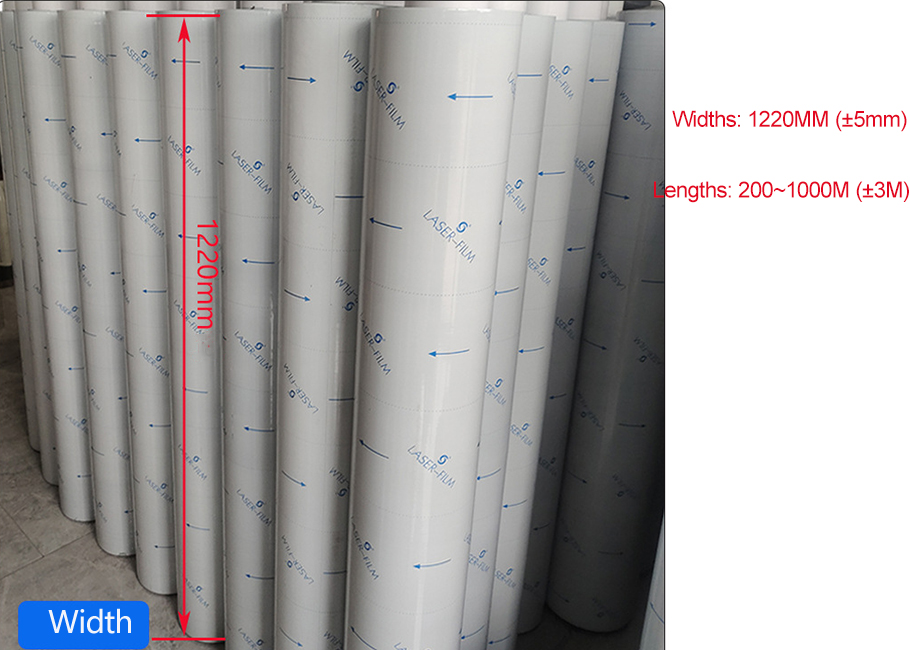

Offering custom and bespoke orders, we can adapt our protection

film parameters to a specific characteristics-thickness, width,

adhesion suitable for your business or special need. As one of the

leading protection film manufacturers in China, we consistently

strive to offer unmatched customer service and ease of purchase,

with most of our products available online – and the option to

order custom protection films through our contact us.